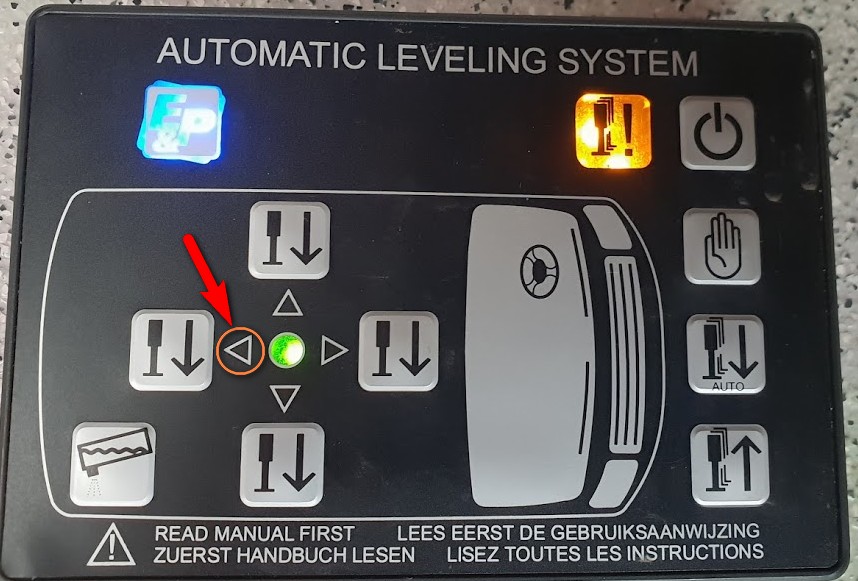

Another question ...what do the little arrows by the green centre dot/light signify? Sometimes there's one, sometimes two when the jacks are down and the green light in the middle is green (i take that as level if its green).

Cheers

Cheers