I have very little space around my lithium battery and have to make some adjustments to the current wiring to install a small inverter.

The maximum discharge rate of the battery is 100amps.

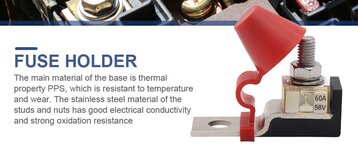

1 of these

attached directly to the battery would cut down on the number of wires I would need to fit into the space I have. BUT the fuses to fit all seem to be rated at 58volts - so what amperage fuse would I need ??????

attached directly to the battery would cut down on the number of wires I would need to fit into the space I have. BUT the fuses to fit all seem to be rated at 58volts - so what amperage fuse would I need ??????

Another question again to reduce the number of wires - the inverter will be 50 cm from the battery and it has an on/off switch so is another switch necessary at the battery end of the 50cm wire.

thanks if you can help with this.

The maximum discharge rate of the battery is 100amps.

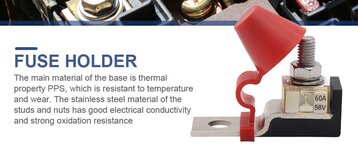

1 of these

attached directly to the battery would cut down on the number of wires I would need to fit into the space I have. BUT the fuses to fit all seem to be rated at 58volts - so what amperage fuse would I need ??????

attached directly to the battery would cut down on the number of wires I would need to fit into the space I have. BUT the fuses to fit all seem to be rated at 58volts - so what amperage fuse would I need ??????Another question again to reduce the number of wires - the inverter will be 50 cm from the battery and it has an on/off switch so is another switch necessary at the battery end of the 50cm wire.

thanks if you can help with this.